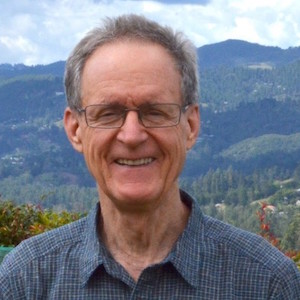

In April, six years after founding Mercury Free Mining (MFM)—an industry nonprofit dedicated to helping artisanal and small-scale gold miners (ASGM) around the world find an alternative to using toxic mercury when extracting gold from ore—jewelry designer Toby Pomeroy celebrated a major milestone: Together with its partners at the Alliance for Responsible Mining (ARM), MFM performed a successful field test of the Goldrop, an innovative system for mercury-free processing of gold ore, in three communities in Colombia’s Chocó and Antioquia gold-mining districts.

“After six years of working on Mercury Free Mining, we’ve substantively turned a corner,” Pomeroy says. “It’s very exciting.”

The success of the tests, which were supported by a grant from GIA, bodes well for the Goldrop’s growing acceptance. Developed by John Richmond of Sluice Goose Industries, the system is portable, easy-to-use, and—at $3,500—cost-effective. Early findings indicate that it can capture more fine gold than traditional processing methods, including those using mercury.

Pomeroy, who is based in Corvallis, Ore., spoke to JCK about how the Goldrop functions, the benefits of the system, and why the use of mercury is “like a sword of Damocles hanging over the industry.” (The interview has been condensed and edited for clarity.)

In founding Mercury Free Mining, why did you focus all your energies on eradicating mercury from gold mining as opposed to other issues facing artisanal communities?

I’ve been a follower of Peter Diamandis, the founder of the XPrize Foundation, and he asked a question on a podcast around the fall of 2016: “If you could make a difference in a billion people’s lives in the next 10 years, how would you do that?” It was immediate to me that the biggest problem for me as a jewelry designer is mercury. Millions of people suffer from it. Watching how we can solve virtually anything using technology, computers, the crowd [sourcing], I thought to myself, “I’m doing this, it’s really worth my life.”

I came up with the idea of raising a million-dollar prize in the jewelry industry to fund a breakthrough solution. But people were not jumping to be a part of this moonshot. With our board, we backed off and [decided to] find projects on the ground where we can demonstrate that mercury is, in my view, truly our most pressing issue.

I don’t think there’s a larger issue the jewelry industry could attend to right now, especially when it comes to what’s becoming increasingly important to our customers: ESG [environmental and social governance] and DEI [diversity, equity, and inclusion]. Mercury has a far bigger impact than blood diamonds—it’s entirely global, and it’s affecting 100 million people. Artisanal and small-scale gold miners and their communities are the greatest source of mercury pollution on the planet.

How did the Goldrop come to fruition?

John had been at a gold prospectors’ show in Texas and he ran into a guy named Dave who knew me and what I was committed to. Dave told John, “You should get in touch with Toby.” John lives about 20 minutes away from me. His company are industrial rebuilders, working on heavy equipment.

But he had invented this elutriation process for gold miners. It’s basically a term for the physics of having a rising flow of air or water that suspends lighter material while it allows heavier material to pass by. In this case, it’s an upward flow of water that carries away the lighter minerals and allows gold to settle at the bottom. The gold drops into this jar at the bottom of this processor.

Dave told John, “You should meet this guy.” John had no idea about mercury in gold mining. When we met, it inspired him and gave him a whole new purpose.

Why was John working on a gold processor in the first place?

His brother was a gold prospector, and John watched him panning and said, “That’s ridiculous, it takes so long. There’s got to be a better way.” Being an inventor, he had insights and actually dreams about how to do it. He’s been developing the system and has made maybe 10 to 12 iterations. It’s been a trial-and-error test of ingenuity.

John and I connected in 2017 or 2018, and not that long after, I founded MFM. I started working with GIA in 2019 on how we might move forward with addressing this issue.

Tell us about the lab tests you performed with the Goldrop.

We started talking with GIA, ARM, and MFM about how we could demonstrate innovative ore processors in the field so we could get information and forge emotional connections with the people that are mining our gold and having to use mercury because there’s no alternative.

We spent the better part of two years looking at various mines with ARM. Then Caelen Burand, a brilliant mining engineering student at the University of Arizona, came into the picture. It’s been kind of magical—everything I needed to fulfill this project has just shown up. The people I’ve met, the opportunities I’ve had, the board of directors, and then Caelen.

This project is in his wheelhouse. He loves mining, he loves geology. He’s now working on his Ph.D. on exactly this. He analyzed some of the ores we’d sampled and found we couldn’t use them because they had arsenic, so we started looking again and with ARM came up with two communities in Peru: Cecomip and Cruz Pata, a neighboring mine in the Ananea district.

We started conversations with both mines through ARM, which has been working with them. We imported their ore samples. We shipped some to a processor in Australia, some to Lima, some to Medellín [Colombia], and the rest came to the University of Arizona.

We distributed those samples to three different processors; one was the Goldrop. They analyzed the processors, and the Goldrop—through this assessment of its capture rate—was clearly the winner. So GIA funded us for this project in Peru.

But Peru had an election, and the most violent strife was in the Puno district where these two mines are, so ARM couldn’t travel there, and we had to look for alternatives. We went to one of their programs, a WWF program in the community of Unión Panamericana in Colombia’s Chocó region. They arranged for us to travel there in April: me, John, and my translator, Sebastian, to find out if miners are interested in participating in trials.

My son Andrew happened to be working in Colombia remotely and came with us as a photographer. He is a computer programmer who works for a company called New Relic in Portland—he’s been in Bogotá, Cartagena, Medellín. I got to see more of him in Medellín than at any time since he left for college.

We visited places that were alluvial and places that had hard rock crushed ore. It was better in many ways than if we had simply gone back to the two mines in the Puno district in Peru, because we got to process different kind of ores. It was basically an extension of the lab test that had determined that Goldrop was capable of capturing more gold than miners were able to do using mercury. We really wanted to see that in the field.

The miners all said, “Great, we can use this, this will be beneficial.” One miner was quoted in the press release from GIA saying, essentially, “We had no idea how much gold we had been losing.”

What makes the Goldrop superior to other processors?

The Goldrop weighs around 50 pounds; it’s very portable. It will run on a 100-watt solar panel and a small motorcycle battery. The thing will run all day long, even in heavily overcast weather. It pumps away, recirculating its water. It has an incredibly tiny, almost no, environmental footprint.

At one point in Unión Panamericana, we were moving to a new mine site. Two miners went ahead to this mine site and set it up, and by the time we got there, they were set up and running. It took them about 10 minutes. They had been processing the samples that had been prepared.

The system costs about $3,500. Almost everyone said it was really a great price. For the miners in Chocó, it would be a stretch, but it would be accessible. It will process about a ton of ore a day. That’s a common concern—it needs to be scaled up. John has plans for it to be bigger.

You demonstrated the Goldrop at the Lashbrook booth at JCK Las Vegas. What reaction did you get?

We got a great response. A lot of jewelers said, “Is this for me to separate my bench sweep so I don’t have to send them into a refiner?” It got a lot of interest. No one has bought one yet and tested it for that, but it could be a benefit to the industry.

We’ve offered GIA the first right of refusal for a proposal to take this Goldrop now and do a next stage of testing. We want to set it up in interested communities, have them trained for greatest efficiency, and also train them in the dangers of mercury use and in tailings. We want them to be aware of the Goldrop, know how to operate it, how to maintain it, and proceed with repairs.

What’s next?

ARM and MFM are codesigning a testing program that will go to four mines: two in Peru and two in Colombia. We’re suggesting three months, starting with training. Then we’ll have them report back. The biggest issue in mercury-free mining processing is that miners do not continue to use it. We want to make sure they have proper support.

We all know it’s easiest to do what we’ve always done, and it’s challenging to step into something new. We know they’ve been using mercury for centuries. Even though it’s harmful, and most of them know that it is, most don’t focus on that because there’s no alternative. If they’re not more profitable, they will not use this method. And they need to have that support. It needs to be culturally accepted.

So far our feedback is only anecdotal. Miners have said this is great and very promising, but now we need to do side-by-side comparisons so we can document what the miners produce using mercury and what Goldrop produces. We need a third party to document these tests. I’m thinking a university in the U.S. or Colombia. We’re going to propose this grant. I want to be in the field in July. I know that sounds really optimistic.

I’ll be speaking at the State of the Art Jewelry Summit at Harvard on June 23. I’m on the panel for demystifying ESG. I’m going to propose that the industry take on the issue of mercury in gold mining as a mission, so we actually put a stake in the ground.

Top: A gold miner works the Goldrop system. (Photos courtesy of MFM)

Follow JCK on Instagram: @jckmagazineFollow JCK on Twitter: @jckmagazine

Follow JCK on Facebook: @jckmagazine