In November, I joined a small group of journalists on a tour of the Lightbox lab-grown diamonds facility in Gresham, Ore., a suburb of Portland. JCK news director Rob Bates made the same trip in the fall of 2018, but the factory, which is owned by De Beers subsidiary Element Six, was still a construction site when he visited.

When I visited, the 53,484-square-foot structure, which officially opened in October 2020, was in full swing, providing an enlightening glimpse of the process involved in growing diamonds using the chemical vapor deposition (CVD) method.

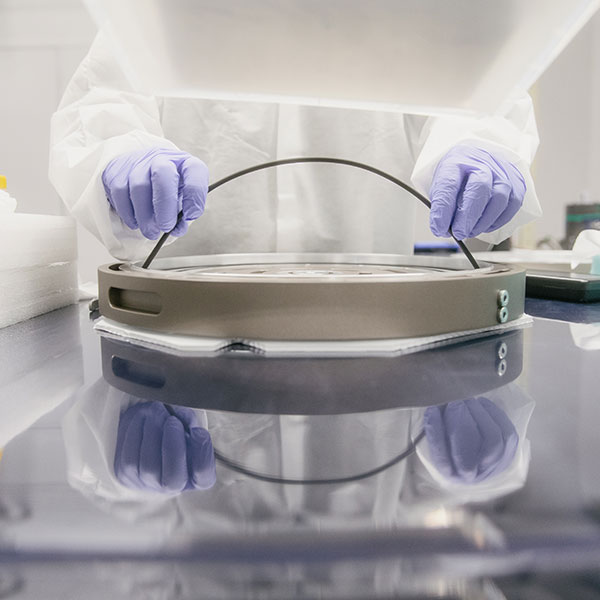

After our group donned steel-toe boots, white lab coats, and safety glasses, we commenced the tour. Had I not known what the factory was producing before I arrived, I might have guessed—based on the hum of the gleaming white machinery and high-tech vibe—that it was making semiconductors, which wouldn’t have been a bad guess. The space resembles a high-end data center precisely because it was built by data center designers.

What else surprised me? Below are a handful of my observations.

Why Gresham?

“We looked broadly across the world for somewhere where we had reasonable costs per kilowatt hour,” Adam O’Grady, the general manager of the facility, told us. The renewable energy provided by the Columbia River combined with the Pacific Northwest’s cool climate are ideal for a lab-growing operation, where energy costs are high (and getting higher).

Synthesis is a 24/7 endeavor.

The factory is staffed 24 hours a day, seven days a week in order to optimize the growing process. O’Grady noted that about half of the factory is taken up by what they call the “synthesis hall,” essentially a forest of reactors that contain batches of diamonds in varying stages of growth.

The command center features numerous screens displaying things like temperature, status of gas supplies, and different performance metrics focused on yields and targets. Everything factory workers do is geared toward efficiency. “What’s happening on my shift, and how can I make it better?” is how O’Grady put it.

The process is highly technical, but there’s magic here too.

The CVD process begins when a thin substrate of polycrystalline diamond film is placed inside a sealed chamber and heated to extremely high temperatures (think 6,000 degrees Celsius!). A cocktail of carbon-rich gases (usually methane combined with other gases) fills the glowing chamber and, over time, the substrate grows. (Incidentally, thousands of gallons of recycled water course through pipes beneath the building every minute to keep things cool.)

“Roughly, we’re producing a 1 carat stone every few minutes,” O’Grady said.

Overall, it takes a couple hundred hours to grow a couple hundred stones. Now that the factory is fully operational, it is expected to produce 200,000 polished carats of grown-in-the-USA diamonds per year.

The longer a stone remains in the chamber, the bigger it gets. (A 2 ct. diamond requires about three weeks of grow time.)

An “as grown” diamond is wild looking.

In general, CVD yields much more consistent, inclusion-free material, and that’s certainly the case at Lightbox. When the growing process is complete, what emerges from the chamber looks like a square hunk of colorless mineral that’s flawless and flat on top and rough around the edges (“as grown” using the parlance du jour).

Lightbox also produces pink and blue diamonds (but no yellows) that derive their color from the different recipes of gases that permeate the chamber, as well as through post-growth treatments.

Lightbox is on the loose!

The company is now selling loose diamonds up to 2 cts. in size directly to consumers. Unlike natural diamonds, whose prices rise exponentially with their size, Lightbox follows a linear pricing strategy: 1 ct. stones retail for $800, and 2 ct. stones are $1,600.

All in all, my Lightbox factory tour impressed upon me the highly technical nature of lab-grown production. It’s a far (far) cry from how natural diamonds are formed—and here I think back to 2006, when I had the opportunity to visit two De Beers mines in southern Africa—but then again, it yields a 2-carater in weeks, not epochs. Time savings have got to count for something!

Top: A worker at the Lightbox lab-grown diamonds facility in Gresham, Ore. (photos courtesy of Lightbox Jewelry).

Follow JCK on Instagram: @jckmagazineFollow JCK on Twitter: @jckmagazine

Follow JCK on Facebook: @jckmagazine